Co-Efficientof variation of fibre diameter

Reference section

According to Palmer, the co-efficient of variation (CV) of fibre diameter of three-component blend can be predicted as follows:

C2 = x1 C12 + x2 C22 + x3 C32 + 5,29 X 104 {x1 x2 (log10 d1 )2

d2

+ X2 x3 (log10 d2 )2 + x3 x1(log10 d3 )2}

d3 d1

Where C = CV of blend

C1 C2 and C3 are the CV’s (in %) of each component

d1 d2 and d3 are the mean fibre diameter (in (m) of each component, and x1 and x2 and x3 are fractions of each component blended.

In a two-component blend x3 = 0.

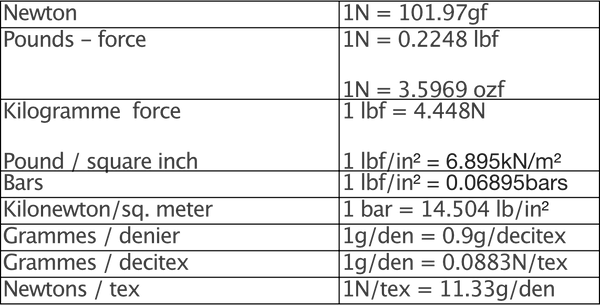

CONVERSION TABLES

Imperial to Metric and Metric to Imperial

[Key: 1 inch = 25.40 Millimetres, 1 Millimetres = 0.039 inches etc.

A bar is a unit of pressure in CGS units and is a pressure of 106 dynes per sq. cm. In practical terms it is equivalent to an ʻatmosphereʼ or a pressure of 76cm of mercury.

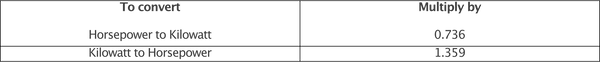

power

power

power

power

power

ELASTICITY

Elasticity = The amount by which a material recovers to its original length after the release of for

Elasticity Recovery [%] = bc - bd x 100

bc. 1

Initial Modulus

This can be quoted in many ways, e.g. as:

✔ Force at a given extension

✔ Tenacity at a given extension

✔ Force at 100% extension extrapolated from the tangent to the initial curve

✔ Tenacity at 100% extension extrapolated from the tangent to the initial curve

Fibre Densities

Reference section

HUMIDITY

Mechanical Engineering

Standard Atmospheric Conditions for Textiles:

65% RH ± 4%

20°C ± 2°C

Temperature:

°F to °C = (°F-32) x 5° C to °F = (°C x 9) + 32

9 5

Relative Humidity:

For most practical purposes, this is equal to the ratio of the mass of water vapour actually present in unit volume of moist air [absolute humidity] to the mass in unit volume of saturated air at the same temperature. [For definitions see BS 1339].

Chemical Hygrometer:

The values below are grams of water contained in a cubic meter [m3] of saturated air at the total pressure of 101 325 Pa [1013 mb].

CORRECTION FOR RELATIVE HUMIDITY IN WOOL FIBRE DIAMETER MEASUREMENT

The standard method of measurement of wool fibre diameter requires an atmosphere of 65% relatve humidity; measurements made under other conditions will be in error to some degree.

The table gives the correction in microns to be applied to values obtained by air-flow or projection microscope methods to give the diameter at 65% r.h.

The relative humidity should be read from a hygrometer mounted near testing area. The sample should have been in the testing room for sufficient time to reach equilibrium with the atmosphere.

Correction table for effect of relative humidity on wool fibre diameter measurements

Micronaire Conversion Table

The above figures are a guideline only.

Environmental Conditions in Spinning Mills

The inter-relationship between temperature and moisture content in the air of vital importance to obtain the best conditions for spinning. Failure to maintain the optimum conditions may result in poor runnability, excessive end breakage, low machine efficiency and a higher fault rate in all processes.

model stress strain curve

a-b = Hookean region or elastic region - stress is proportional to strain

b = Yield point - the elastic limit

b-c = Region of primary creep - extension recoverable with time

c-d = Region of secondary creep - permanent elongation

d-e = Region of difficult extensibility

e = Breaking force on y axis, % extension at break on x axis

Moisture in Textiles

% Regain = Weight of water in the sample x 100

Oven dry weight of the sample

% Moisture = Weight of water in the sample x 100

Original total weight of the sample

Conversions between Moisture Content & Regain

To convert from moisture content to regain or vice versa, use the following equations

(in which M = moisture content, R = regain):

M = 100R and R = 100M

100 + R 100 - M

* In the EEC Directive the following definitions are given:

1. Wool. Fibre of sheep’s fleece

2. Alpaca, llama, camel, cashmere, mohair, angora, vicuna, yak, guanaco, preceded or not by the word ‘wool’ or ‘hair’. Hair of the following animals: alpaca, llama, camel, cashmere goat, angora goat, angora rabbit, vicuna, yak, guanaco.

3. Fur or hair with or without an indiction of the animal species [for example, bovine hair, goat’s hair, horse hair]. Hair of various animals other than those mentioned under 1 & 2.

*Note: Mohair fibre is from an angora goat, “angora” is from an angora rabbit.

Noise Basic Data

Decibels

In measuring noise one factor measured is sound pressure level. The sound pressure at the ‘threshold of pain’ is about one million times that at the ‘threshold of audibility’.

Noise levels are given in decibels (dB). The decibel scale is logarithmic and in acoustic work is referred to a reference pressure equivalent to the threshold of audibility, 0.0002 dyne/cm2 (0.00002 N/m2).

This decibel scale represents the range of pressure levels from threshold of aubility to threshold of pain by a range of 120 decibel units.

TYPICAL WOOL FIBRE DIAGRAMS

Decibel arithmetic

Because the decibel scale is logarithmic, care is essential in manipulating decibel values.

Two equally noisy sources together produce 3 dB more than each separetely. Thus, for example,

80 dB + 80 dB = 83 dB

96 dB + 96 dB = 99 dB

Noise at a point receiving all the energy from a multiplicity of equal sources.

Specific Gravity of Fibres

Specific gravity of natural fibres

Effect of regain on specific gravity of wool

Specific gravity of wool at different regains

Useful Statistical Terms

Tensile Properties of Fibres

USEFUL FIBRE DATA

* dtex is a measure of linear density. dtex = mass in grams of 10,000 metres.

Denier = mass in grams of 9,000 metres.

Yarn Numbering Systems

Constants for conversion of INDIRECT systems

Wira Instrumentation Ltd

Unit 6, Great Russell Court, Fieldhead Business Centre, Bradford