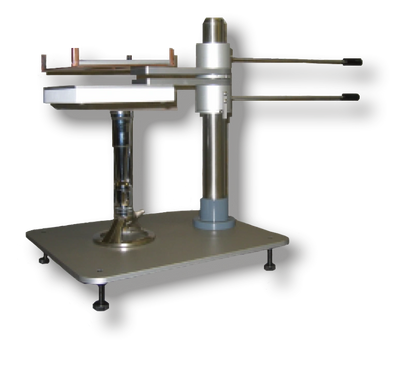

Contact Heat Tester

Apparatus for the testing of protective clothing

The Wira Contact Heat Tester apparatus for the testing of protective clothing is used in the determination of the contact heat transmission through protective clothing or its material. The test apparatus has been developed to meet the requirements of EN ISO 12127-1:2015 (replaces EN 702:1994). Protective clothing, including hand protection, is designed to protect against high contact temperatures. The test method is restricted to contact temperatures from 100°C to 500°C.

Test Method

A heating cylinder, manufactured from Nickel, is heated up to the contact temperature. The temperature of the cylinder is controlled by means of a PID controller.

The specimen is placed on a calorimeter and the calorimeter is raised at constant speed so that the specimen makes contact with the surface of the heating cylinder. The temperature is monitored, and the threshold time is determined as the time taken for the temperature to rise by 10°C. The equipment is supplied with an interface box, connecting the calorimeter to a PC. The software supplied with the interface box enables the temperature to be monitored and the temperature trends to be saved and printed.

Specification:

Dimensions:350mm(W),350mm(D), 420mm(H) Power: 220 Volts, 3 Amps

Standards: EN ISO 12127-1:2015

Order Code: PCT:005

Contact Heat Tester LFT2021 (pdf)

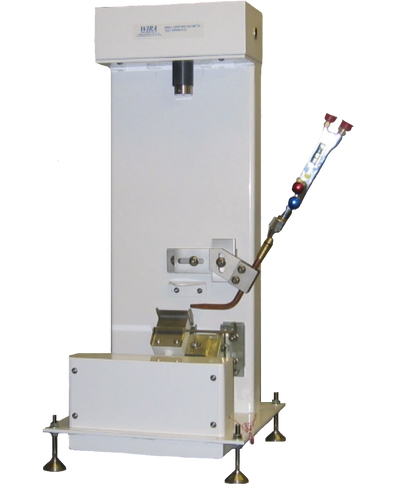

DownloadFlame Test Apparatus

Evaluate the heat transmission of materials and material combinations when exposed to a flame.

Protective clothing is expected to provide protection against heat and fire. The Wira flame heat test apparatus determines the heat transmission on exposure to flame.

Test Method

The specimen is subjected to a flame from a gas burner. Heat passing through the specimen is measured by means of a calorimeter that is in contact with the back of the material. The time is recorded for the temperature to rise to 24 degrees celsius. The specimen support frame is mounted on a support stand so that the specimen is supported at the required distance above the gas burner.

Key Features

✔ Removeable test frame for easy mounting of samples

✔ Movement of guard initiates recording

✔ Recording software

Specification:

Dimensions: 300mm(W),400mm(D), 430mm(H) Power: None

Gas Supply: Propane

Standards: BS EN ISO 9151:2016

Order Code: PCT:002

Flame Test Apparatus LFT2021 (pdf)

DownloadMolten Metal Test Apparatus

For assessing the heat penetration resistance of materials intended for use in clothing to protect a

In the metal industries, protective clothing is expected to protect against heat and molten metal. The Wira Molten Metal Test Apparatus subjects the sample to a controlled application of molten metal.

Test Method

An embossed PVC film, representing human skin, is placed behind the test specimen. The metal is heated up in a furnace (optional) until molten and the crucible is transferred to the apparaus in a special holder and handle. A stepper motor controls the tipping of the crucible as the molten metal is poured onto the specimen that is supported at an angle.

The PVC film is then inspected for damage. The test is repeated using greater or smaller amounts of molten metal until minimum damage to the film is observed.

Key Features

✔ Stainless steel enclosure with door interlock

✔ Adjustment for impact angle and pouring height

✔ Pouring speed controlled by stepper motor

Specification:

Dimensions: 475mm(W),400mm(D), 750mm(H) Power: 220 Volts, 1 Amp

Standards: BS EN ISO 9185:2007

Order Code: PCT:003

Molten Metal Test LFT2021 (pdf)

DownloadSmall Drops Molten Metal Test Apparatus

Applies to any pliable material, or assembly of materials

To evaluate the behaviour of materials used for protective clothing when such materials are struck by small liquid metal splashes, especially when molten steel particles are projected against the material.

Clothing designed for protecting wearers against small splashes of molten metal is often submitted to high thermal loads and so an important function is the resistance to heat transfer through the protective material.

Test Method

Drops of molten metal are formed by melting the ends of a steel rod by means of an oxyacetylene torch. A rod is lowered at a controlled speed to create a steady stream of drops. The drops fall vertically into a funnel which guides the metal drops onto the test specimen. Behind a specimen a temperature sensor monitors the temperature. The number of drops are counted as the temperature is monitored and the temperature rises by 40°C.

Key Features

✔ Stainless steel enclosure with door interlock

✔ Adjustable speed for feed of a metal rod

✔ PTFE guide funnel ✔ Recording software

Dimensions: 320mm(W),330mm(D), 750mm(H) Power: 220 Volts, 1 Amp

Standards: BS EN 348:1992

Order Code: PCT:004

Small Drops Molten LFT2021 (pdf)

DownloadResistivity Measurement of Protective Clothing

Apparatus for measuring the surface resistivity and electrical resistance through a material.

The Electrostatic properties are an important factor for certain items of protective clothing, in particular where electrostatic discharge can cause ignition. One factor that can be measured is the surface resistivity and the vertical resistance of protective clothing materials. Electrodes are placed either on the same surface or on opposite surfaces of a material. The electrodes are connected to a Tera-Ohmmeter which applies a DC potential of 500 volts to determine the electrical resistance.

Two-Part Test Electrode

The Two-Part Test Electrode consists of a Central electrode and an Annular electrode. The Central electrode is a 50.4 diameter metal disc which makes contact with the surface of the material under test and a 67.6mm diameter guard plate, separated by a high insulating material. The Annular electrode is a metal ring with inside diameter of 69.2mm, leaving an airgap between the Central electrode and the Annular electrode. The combined contact pressure of the two parts is 10N. To perform the Surface Resistivity test (EN 1149-1), the material under test is placed on the insulating base plate, which in turn is placed on the Earthed steel plate, the two part electrode is then placed on the upper surface of the material and the Tera-Ohmmeter is connected between the Central and the Annular Electrodes. To perform the Vertical Resistivity test (EN 1149-2), the material under test is placed on the Base Plate electrode, a 110mm diameter metal disc with insulating material on the lower side. The two part electrode is then placed on the upper surface of the material and the Tera- Ohmmeter is connected between the Central and Base Plate electrodes. The Annular electrode is connected to earth to form a guard ring.

Key Features

✔ Tera-Ohmmeter

✔ Two-part Test electrode used for Surface Resistivity and Vertical Resistivity test

✔ Base Plate electrode for Vertical Resistivity test

✔ Steel base plate for Surface Resistivity Test

✔ Conforms to EN 1149-1 and EN 1149-2

Dimensions: 440mm(W) x455mm(D)x131mm(H)

Weight: approx. 15kg

Measurement Range: 104Ω - 2 x 1014Ω (at 100VDC test voltage)

Test Voltage: From 1 VDC to 1500 VDC in 1VDC steps

Main Voltage: 100-240 VAC +/- 10%, 50-60 Hz, Single Phase

Power: 700 VA Max

Order Code: PCT:006

Surface Resistivity LFT2021 (pdf)

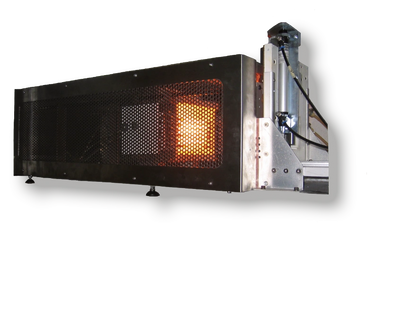

DownloadRadiant Heat Tester

Apparatus for the testing of protective clothing.

Protective clothing against Radiant Heat may be used in a wide range of applications. It may be required to protect workers against a low intensity heat for a long period of time, alternatively the intensity may be rated as mediumorhigh,butthetimeperiodwill be adjusted accordingly.

Test Method

The Wira Radiant Heat Test Apparatus may be used to test the material in two ways. In the first test the specimen is subjected to a level of thermal radiation. In order to represent the most severe conditions for the material, very little heat is conducted away from the sample. Changes in appearances are recorded. In the second method, a calorimeter is placed behind the sample, and so conducts heat away from the back of the material. The temperature rise is recorded against timeandtheheattransfersare determined.

The radiation source consists of silicon carbide heating rods. The test frame is constructed from a non-combustible board, and is easily adjusted to set the required heat flux density. A water-cooled protective screen protects the heat source until the test begins.

Key Features

✔ Removable test frame for easy mounting of samples

✔ Tensioning weight

✔ Pneumatic operation of cooling screen

✔ Recording software

Dimensions:1250mm(W),475mm(D), 450mm(H) Power: 220 Volts, 35 Amps

Standards: BS EN ISO 6942:2002

Order Code: PCT:001

Radiant Heat Tester LFT2021 (pdf)

DownloadWira Instrumentation Ltd

Unit 6, Great Russell Court, Fieldhead Business Centre, Bradford