Testing of Fibres & Yarn

WARP TENSION METER

Quickly measure the tension of warp yarns in weaving

The compact WTM:003 Warp Tension Meter has been developed to measure the tensile forces in warp threads. The combined forces of a warp of 50 mm in width is measured by a measuring head with a 100mm roller.

The results are shown on a separate display instrument. Storage of AVG, LAST, MIN, MAX, PEAK-MIN, PEAK-MAX tension values during a measuring period can be set by the operator.

Test Method

Swivel the lever towards the handle to move the measuring roller downwards. Hold the measuring head over the yarn group, so that it runs parallel to the measuring feeler and the support rollers. Guide the measuring roller through the yarn, turn the measuring head by 90° and swivel the lever forwards, away from the handle, to move the measuring roller upwards into the measuring position.

Key Features

✔ Tension range 5-200 N

✔ Portable

✔ Easily engaged and disengaged

✔ Measure at any point over width of loom

✔ 4 memory modes

✔ Data storage

✔ Electronic damping for stable readings

✔ Includes USB connection

Specifications

Measuring Rollers: 2 x 22mm ball bearing mounted rollers, total 50 mm

Width of outer rollers: 100 mm, ball bearing mounted

Frame Height Adjustment: 24 mm

Housing Material: Anodized Aluminium

Frame Dimensions: 108 x 138 mm

Nominal Weight: 1000 g

Order Code: WTM:003

WarpTensionMeterLTF2021 (pdf)

DownloadDUROMETER/HARDNESS METER

To measure the winding density (hardness) of a wide range of textile packages, including bobbins, be

A range of 6 models with different ball sizes and working faces, the slightly curved working face fits to small bobbins, and the flat working face for bobbins and other packages with diameters over 400 mm. The ball shaped indenter prevents damage to bobbins with three different sizes:

2.5 mm diameter ball for closely wound bobbins of synthetic, finished yarns and filaments.

5 mm diameter ball for loosely wound bobbins of synthetic fibre yarns and closely wound natural fibre yarns and threads.

10 mm diameter ball for very loosely wound bobbins of thick yarns such as carpet yarns.

The spring-loaded outer ring of the main body of the tester is pressed downwards until the edge of the ring reaches the red mark, this ensures a constant pressure and prevents measuring errors between operators.

Key Features

✔ 6 different models

✔ Constant pressure system

✔ Ball-shaped indenter

✔ Optional memory pointer

Dimensions: 50 x 58 x 110 mm

Nettweight: 300g Power Requirements: 0.2kW

Order Codes of different models:

DUR:001 2.5 mm diameter ball, curved face

DUR:002 5 mm diameter ball, curved face

DUR:003 10 mm diameter ball, curved face

DUR:004 2.5 mm diameter ball, flat face

DUR:005 5 mm diameter ball, flat face

DUR:006 10 mm diameter ball, flat face

DurometerLFT2021 (pdf)

DownloadBOARD WINDER

TO ASSESS YARN EVENNESS IN COMPLIANCE TO ASTM STANDARDS

Fast and accurate results. Single-traverse board winder for yarn inspection and sample viewing, used to detect irregularities in the yarn.

Can accommodate either tapered (155 x 255 x 600 mm) or rectangular boards (255 x 600 mm). A special pretension device ensures constant tension of the yarn as winds on the cards and the yarn pitch is selected by a pulley system.

Key Features

✔ Variable Speed, 30-300 rpm

✔ Automatic stop ✔ Pretension device ✔ Bracket to hold bobbins

Dimensions: 950mm (W), 360mm (D), 600mm (H) Power Requirements: 0.1 kW Conforms to: ASTM D2255

Order Code: BWD:001

BoardWinderLFT2021 (pdf)

DownloadCARD WINDER

For preparation of yarn sample cards and test cards for colour matching

Power driven inspection card winder, popular for the preparation of sample cards and colour test specimens. Can accommodate cards of length 150 to 320 mm and a maximum width of 100mm. Amaximum of 12 separate yarns can be wound onto the same card. A pretension device ensures constant tension of the yarn as winds on the cards. Dual speed control ensures total flexibility of the wrap and lay and a pre-set counter determines the number of layers.

Key Features

✔ Variable Speed, 50 - 850 rpm

✔ Automatic stop ✔ Dual speed control ✔ Pretension device

Conforms to ASTM D2255 Dimensions: 820mm (W), 600mm(D), 600mm (H) Net Weight: 55 Kg Power Requirements: 0.1 kW

Order Code: CDW:003

CardWinderLFT2021 (pdf)

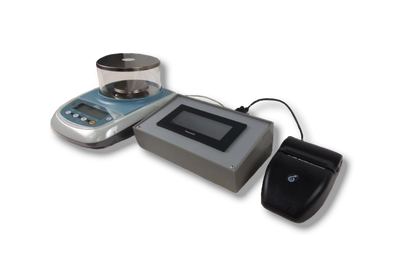

DownloadCOUNT BALANCE

Specially designed for yarn count testing

Accurate measuring device to determine the linear density of yarn.

The Wira Yarn Count Balance is the ideal device for the analytical testing of yarn count.

Readings can determine the linear density (mass per length) of yarn skeins and the GSM (mass per sq m) of fabrics. The Wira Yarn Count Balance gives the results in Tex, dTex and other yarn count systems such as Metric count (Nm), English count (Ne), English cotton count (Nec), Denier (Td), etc.

This apparatus allows the user to obtain results without operating on external devices e.g. calculator, excel.

Storage memory of up to 100 results. Portable or Lab versions available.

Accessories:

Printer: Order Code YCB:PRT

Paper for printer: Order Code YCB:PPR

Software for Statistical Analysis: Order CodeYCB:SFT

Key Features

✔ Includes weighing balance with capacity of 400g / accuracy of 0.001g

✔ Printed results

✔ Convenient and easy to use

Dimensions: 170 x 190 x 110 mm Power Supply: 5W; 110/230 Vac - 50/60 Hz Weight: 8 kg

Order Code: YCB:001

Count Balance LFT2021 (pdf)

DownloadDIGITAL TWIST TESTER

DETERMINE THE TWIST CONTENT OF A WIDE VARIETY OF YARN TYPES

Fast and efficient twist testing with a choice of operation modes.

An advanced testing instrument able to determine the number of twists for single, plied and open-end yarns. An automatic operating and measuring system incorporates an inductive sensor which stops twisting and re-twisting when the test is complete. The instrument includes a choice of test methods, selected via the user-friendly touch screen. Statistical data includes Min, Max, AV, Standard Deviation %, CV % etc.

Includes standard set of pretension weights: 0.5, 1, 2, 3, 5, 7, 10, 15, 40 grams.

Software: Acquires test results via the USB port and saves in a .csv file which can be viewed in a spreadsheet. Printer:Allows printing of results including data input by the operator. Additional weights: 50, 100, 150, 200, 250 grams.

Test Methods:

The following modes of test are available: Single Yarn Test: Untwist-Retwist method of single spun yarns in S or Z twist direction as described in ISO 2061, ASTM D1422. Direct Counting Test: Method of untwisting until reaching straight section of a yarn according to ASTM D1423/D1423M. Dual: Test method suitable for double or plied yarns. Schutz: Suitable for open end yarns according to the 2nd appendix new “Double Test Check” devised by Messrs, M. Kuenym, H.LE Chatelier and R.A Schutz. Manual: Motor digitally controlled by the operator.

Key Features

✔ Automatic operation

✔ Variable test length 1-50cm

✔ CM or Inches

✔ TPM or TPI

✔ Data storage and statistics for up to 20 tests

✔ External potentiometer for motor speed 50-2500 rpm

✔ Black cylindrical support

✔ Includes magnifying glass for examination

Dimensions: 1100mm(W),260mm(D), 280mm(H) Power: 0.2 kW Conforms to: ISO 2060, ISO 2061, ASTM D1422, ASTM D1423

Order Codes:

DTT:004 Digital Twist Tester without printer.

DTT:005 Digital Twist Tester with integral printer

DTT:SWR Application software.

DTT:006 Electric Twist Tester

DTT:007 Manual Twist Tester.

DTT:WGT Additional set of weights.

Digital Twist Testers LFT2021 (pdf)

DownloadELECTRONIC YARN REEL

YARN REEL TO PREPARE SKEINS OF DESIRED LENGTH TO DETERMINE YARN COUNT

Technical details

Swift circumference: 1 metre, 1 yard, or 1.5 yard. Number of Ends: 5, 7, or 10.

Traverse Motion: 25-45mm - determined by the number of ends.

Motor Speed: 150rpm or variable 0-250rpm.

Options Available

YRL:001 - electronic yarn reel.

Available in: 5 Position 1m, 10 Position 1m, 7 Position 1yd, 7 Position 54"

YRL:003 - 5 Position 1m manual yarn reel

YRL:006 - Fractioned wrap reel

Speed Options

Option F: Fixed Speed (150 rpm) Option V: Variable Speed (0 – 250 rpm)

Tensioner Options - PLEASE SELECT UPON ORDER

Option A: Adjustable tensioner bars with separate creel

Option B: Spring tensioner devices with separate creel

Option C: Adjustable tensioner Bars

Option D: Spring tensioner devices

Key Features

✔ Available in a variety of reel sizes

✔ Heavy duty reel

✔ Collapsible arm for easy yarn removal

✔Winds multiple yarns simultaneously

✔ Optional creel

✔ Fixed and variable speed units available

Typical Dimensions: 780mm x 600mm x 560mm Nett Weight: 45kgs Power Requirements: 0.2kW. Conforms to: BS EN ISO 2060:1995; ASTM D1907-01; ASTM D2260-02; DIN 53830

Order Code: YRL:001

Yarn ReelsLFT2021 (pdf)

DownloadAUTOMATIC SLIVER/ ROVING REEL

For the determination of linear density of sliver and roving

Electronic Sliver Reel.

The equipment is specially designed to assist in the determination of the count of slivers and roving. The counter is set to the required length of sliver to be measured, stopping the motor automatically after the required revolutions of the drum.

The electronic brushless motor enables the operator to control the speed of the drum and provides gradual acceleration and deceleration for smooth operation.

The small roller ensures adhesion of the sliver or roving to the drum and a cutting device assists in obtaining an accurate measurement.

Key Features

✔ Variable speed 0-50rpm

✔ Electronic counter

✔ Automatic stop

✔ Bracket to hold bobbins

✔ Available in metric or imperial versions

✔ Counter up to 1000 revs

Conforms to: ISO 2060, ASTM D3776, ASTM D1907. Dimensions: 450 x 260 x 470 mm Nettweight:15kg. PowerRequirements: 0.2kW. Also Available:

Manual version. Order code: SRR:002

Order Code: SRR:003

AutomaticSliverRovingReelLFT2021 (pdf)

DownloadContact Us

Wira Instrumentation

Wira Instrumentation Ltd

Unit 6, Great Russell Court, Fieldhead Business Centre, Bradford